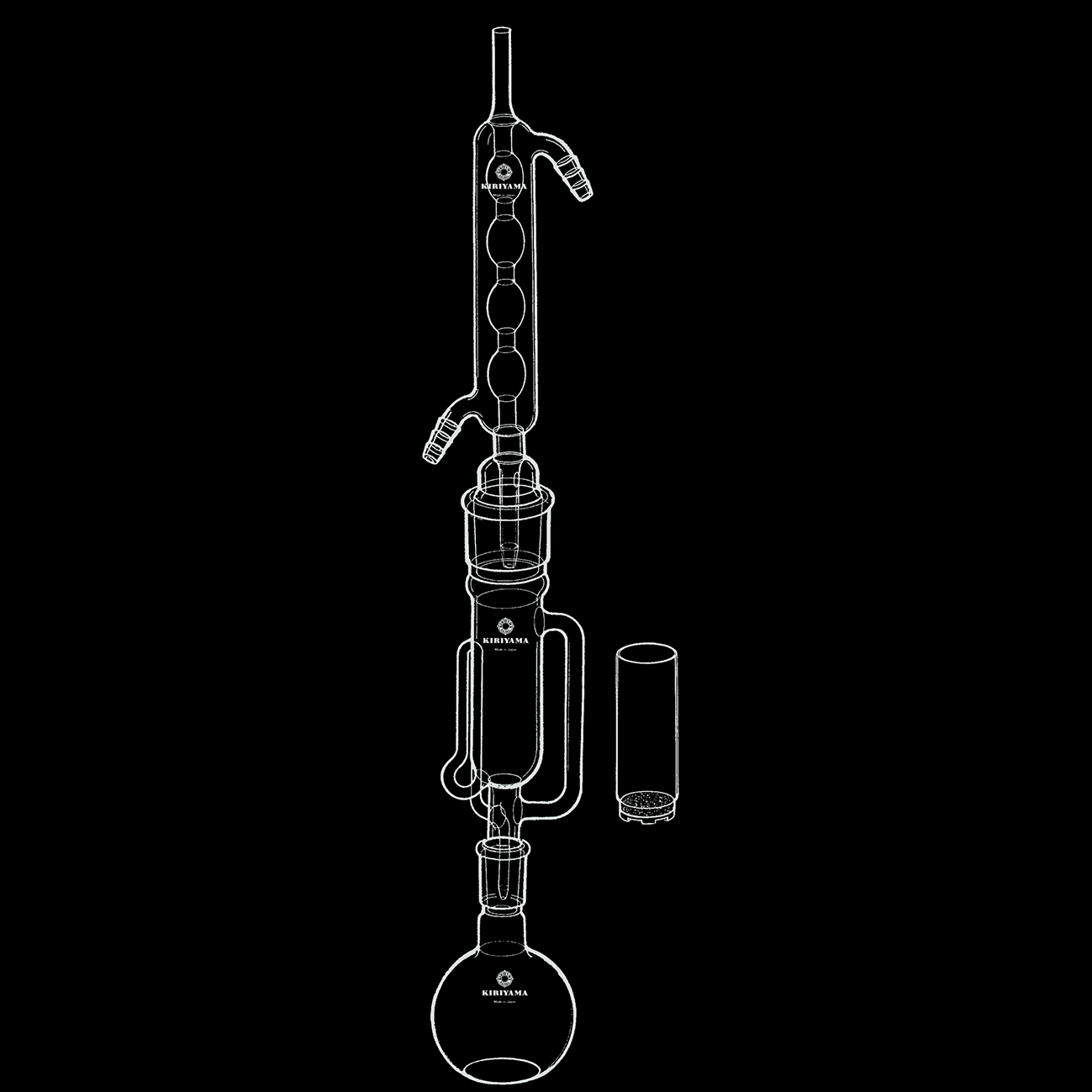

The solvent re-evaporates (boils), and the solutes concentrate as they are left behind in the solvent flask.įigure 2: Diagram of a Soxhlet extractor, reproduced from reference (3).

When the liquid solvent level reaches the top of the siphon tube, the solvent–solute mixture (the extract), is syphoned away from the extractor, and back into the solvent flask. As the solvent vapors hit the condenser (cooled with running water or other circulating fluid), the now liquid solvent flows down onto the sample, where it may permeate into the sample matrix and dissolve the target analytes. As it boils, the solvent vapors rise through the solvent vapor tube sidearm. Solvent (shown in green in Figure 2) is added to the solvent reservoir flask, and mounted onto a heating mantle. In practice, the solid sample is placed into a porous (typically cellulose) extraction thimble, positioned into the Soxhlet extractor, and the device is assembled. The Soxhlet apparatus is shown in Figure 2, and the middle third of the device is the actual Soxhlet extractor. Because of its wide acceptance and the considerable time before suitable alternatives emerged, Soxhlet extraction is considered the benchmark to which other techniques are compared several organizations have volumes of historic data based on Soxhlet approaches. (Of course, he was talking with me about developing a supercritical fluid extraction method to replace his extensive use of Soxhlet.).The wide use of the Soxhlet technique for fats and oils can be gleaned from Table I, which shows selected standard methods using this approach. Personally, about 20 years ago, a food science colleague showed me his laboratory where about 20 Soxhlet extractors were connected to run in parallel. For example, one unsubstantiated story I've heard is about a major food company that performs 20,000 Soxhlet extractions per year across the company, as the confirmatory method after placing a modern instrumental extraction method in each of their plants.

#Diy soxhlet extractor manual#

Because its efficiency of extraction is greater than that of other manual techniques, especially at the time, it gained broad acceptance. Since then, this extraction technique is widely used for fats and oils, as well as other mostly nonpolar solutes, from solid and semi-solid matrices. Soxhlet's original paper (1) concerned itself with the determination of milk fat. ).įigure 1: German chemist Franz Ritter von Soxhlet. (Readers who are fans of Martyn Poliakoff's Periodic Videos may wish to view. The key to this solvent cycling is the constant-level siphon, based on a Pythagoras Cup. So, Soxhlet is more correctly a batch process. This continuous–discontinuous process minimizes channeling of solvent through the sample, as can occur with continuous flow methods. It is continuous in the sense that solvent is continuously evaporated from the solvent reservoir flask and condensed. Soxhlet is discontinuous in that it relies on a number of solvent siphon cycles. Jensen's history on the origins of the device credits a laboratory glassblower, known only as "Herr Szombathy," as a significant contributor to this creation (2). This was the same year, 1879, that a 31-year old Franz Ritter von Soxhlet (Figure 1) became a professor of agricultural chemistry at the Technical University of Munich. In this month's installment, we look back at Soxhlet extraction so that analysts can better appreciate the lessons that are fundamental to today's extractions.Ī highly significant advance in extraction technology, perhaps the most significant occurrence in the field for the century that followed, occurred 140 years ago with the first report of the Soxhlet extractor, a unique continuous–discontinuous device (1). The application of temperature, continuous flow, and preference for flowable samples that make these techniques advantageous were taken from the lessons from Soxhlet extraction, which still has much to teach us. While still widely used, it is being replaced by a number of other techniques, such as ultrasound-assisted extraction, microwave-assisted extraction, and pressurized solvent extraction. Regulatory agencies, trade organizations, and individual laboratories collected a wealth of data based on the technique. For well over 100 years, Soxhlet extraction was considered the gold standard in the analytical extraction of solids. The method was a significant advance in the isolation of solutes from difficult-to-extract solid samples. Franz Ritter von Soxhlet is credited with inventing the extraction technique that bears his name in 1879.

0 kommentar(er)

0 kommentar(er)